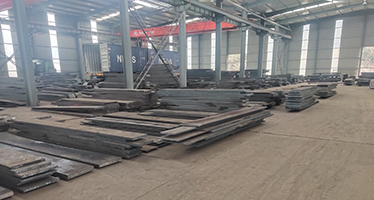

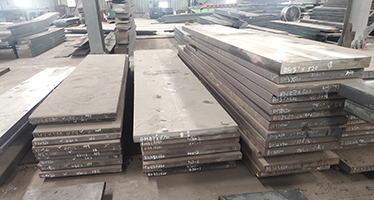

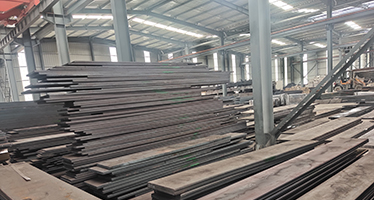

Ningbo Jinhao Mould Material Co., Ltd.Established in 2010, we are dedicated to the production and processing of mold templates, and are a private enterprise specializing in the production of mold templates. The company is located in 1 Jinhao Road, Yuyao City, Ningbo City, Zhejiang Province, China,It covers an area of about 40,000 square meters. Mainly engaged in the custom rolling of Cr12, Cr12mov, 4Cr13, H13, Cr8, SKD11, 6Cr5MnSi, Dc53 and other high quality die steel.

The enterprise combines the production links of mold standard parts production, frame manufacturing, heat treatment, surface processing, etc. to carry out specialized production. Introducing advanced management experience, process technology and advanced equipment of mould steel enterprises at home and abroad, forming the characteristics of mature management, high-quality equipment, advanced technology and strong product competitiveness.

Quality materials, quality workmanship

With dozens of processing machines and customised designs

Component testing, product production and after-sales service teams, assisting each other

Decades of experience in the field technical support

Complete sales and service process with on-site return visits

6 x 8 hour service communication to provide product solutions

102 class high-speed die steelDetailed tool structure drawing is required.The low hardness of die blanks should be 280BHN.(2 steel/4140 steel,...

To resolve the contradiction. cr12mov mold steel carburization is generally divided into two stages: the infiltration stage and diffusion stage,...

The low-temperature quenching process of high speed steel carburized at high temperature is described in detail.Under the carburizing condition of...

Performance requirements.Hardness Hardness is the main technical specification of a die steel. If the mold wants to keep the shape and size...

The general annealing method is to keep the temperature at a low temperature of 1°C or less, while high-speed steel is held for a longer period of...

A large number of bearing steel smelting is carried out by electric arc furnace, which can be developed into various types of primary refining...

Increase the carbon content will make the quenching residual austenite (rR) increase, tempering difficulty. The original M35 steel carbon content...

Why do I need hardened HSS tools?HSS is a high alloyed tool steel that contains a variety of alloying elements. Poor heat transfer and poor...

Abrasion resistance.The main factor affecting the life of a mold is usually the wear resistance of the mold material. Since the mold is subjected...

For materials with high fracture toughness, the crack must have a sufficiently high stress intensity factor at the crack tip, i.e., a large crack...